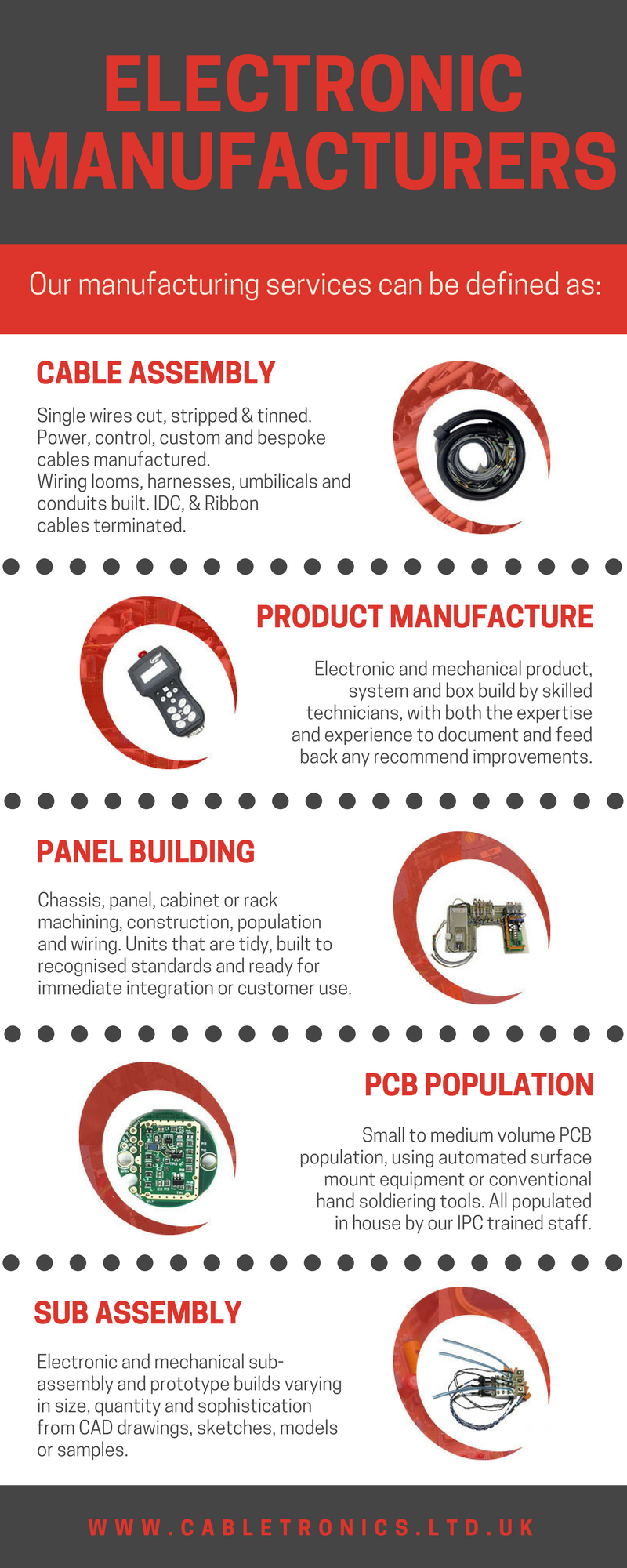

Our workshop has been set up in a way that enables CableTronics to produce a wide variety of wiring harnesses, electronic and mechanical products, box builds, panel assemblies and PCBs.

We concentrate purely on manufacturing bespoke and custom cable assemblies, electronic and mechanical products, box building, panel wiring and PCB population, using highly-trained IPC qualified engineers, with goods delivered by our own transport from our workshop in Biggleswade, Bedfordshire. This means that you pay ONLY for time spent at the bench rather than expensive support, office and administration staff. This keeps our prices low, quality high and deliveries always on time.

Our factory allows for the efficient manufacture of very large cable umbilicals, while another is best suited to undertake small and complex wiring looms and other specialist electrical assemblies.

Also, as you would expect from a company of CableTronics’ standing, we have an array of cable cutting, stripping and crimping machinery for cable assembly.

Furthermore, we have hundreds of hand tools for the manufacture of specialist bespoke and custom cable looms, in addition to a large array of specialist machine tools and test and inspection equipment for product assembly, box building and panel construction. Not forgetting our fully automated SMD assembly line for both surface mount and conventional PCB population.

We also carry a large stock of raw materials that enable a fast response to meet our customer requirements for any urgent cable, product and panel requirements.

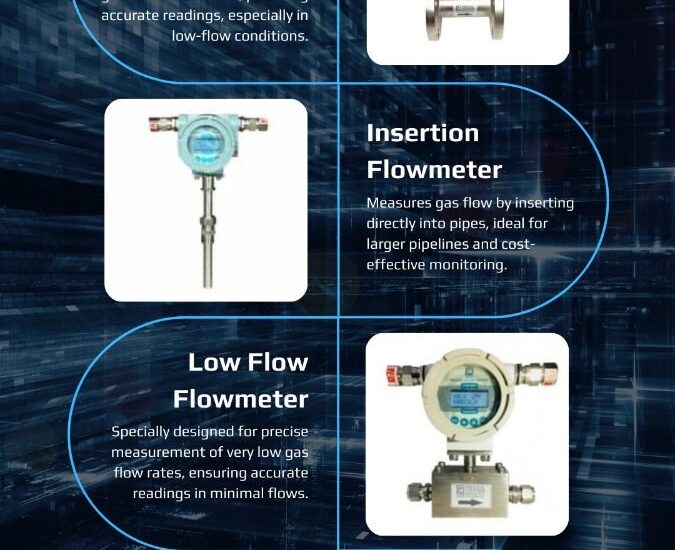

OUR MANUFACTURING SERVICES CAN BE DEFINED AS:

Electronic and mechanical product, system and box build by skilled technicians, with both the expertise and experience to document and feed back any recommend improvements.

Chassis, panel, cabinet or rack machining, construction, population and wiring. Units that are tidy, built to recognised standards and ready for immediate integration or customer use.

Small to medium volume PCB population, using automated surface mount equipment or conventional hand soldiering tools. All populated in house by our IPC trained staff.

Electronic and mechanical sub-assembly and prototype builds varying in size, quantity and sophistication from CAD drawings, sketches, models or samples.

![]()