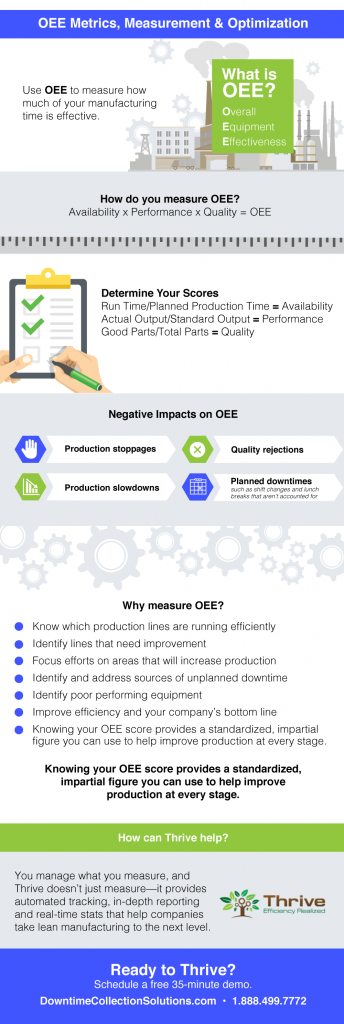

Overall Equipment Efficiency (OEE) takes into account the various components of the manufacturing process like Quality, Performance, and Availability. After calculating all the components result is expressed as a percentage. OEE software helps in monitoring the actual performance of tools. OEE software let you track and reduce equipment downtime. They also help in increasing the overall efficiency of equipment and helps your facility to meet production goals.

It is a cloud-based Software, automated downtime tracking and analysis software which helps in tracking the actual performance of machines. If you are tracking downtime manually, then let the real time OEE (Overall Equipment Efficiency) software do it for you. One can easily determine the product manufacturing time with the help of Overall Equipment Efficiency (OEE) software. You can monitor the real time production from anywhere with the help of internet connection and your password protected dashboard of the software. It helps in analyzing the real time trends according to the shift, line or even SKU.

Know how to determine scores:

Run Time/Planned Production time = Availability

Actual Output/ Standard Output = Performance

Goods Parts/ Total Parts = Quality

How These Systems Work:

They monitor the heartbeat and output of the manufacturing lines to provide tracking performance of real time equipment. These systems help in identifying whether your lines are running and how efficiently they are performing. One can also come to know that how to reduce production time with the help of these systems.

Benefits of OEE (Overall Equipment Efficiency):

One can easily come to know about the real time efficiency of machines.

With the help of these systems, identifying poor performing equipment is very easy.

You can access the performance snapshot from anywhere.

Comparing the current performance of machine with historical performance is very easy.

It helps in tracking live downtime issues.

![]()